Our Process

The key to any great Irish style whiskey is the Triple Copper Pot Distillation process, and our stills are beauties. There are 7 steps in the process overall:

Seven Steps to Making Irish Style Whiskey

Milling

All whiskey starts with a sugar source—usually in the form of starch that is found in grain. Irish style whiskey typically starts with barley (malted and unmalted), a traditional ingredient in single pot still Irish Whiskey since the early 1800s. The first step in the process is to mill the barley by cracking the grain to expose as much of the starch as possible so we can start the next step of the process.

Mashing & Cooking

In this step, we add warm water to the milled barley to start to convert the starch in the grain into sugars. Over the course of about two hours we increase the temperature of this “mash” to convert all of the starch into fermentable sugars. At the end we are left with what looks like a big pot of oatmeal, but is the makings of a delicious whiskey.

Lautering

Lautering separates the sugary liquids (known as wort) from the milled grains in the mash. The mash is transferred to a stainless steel vessel (called a Lauter Tun) with a perforated floor known as a false bottom. The mash is constantly and gently stirred by a big rake and the sugary liquid called “wort” filters through the holes in the floor. Occasionally we spray the mash with more water to extract as much sugar as possible. This is called sparging—a strange word but an important step.

Fermentation

Now we are ready to start making some alcohol. This is done the way nature has been doing it for years—with yeast. Yeast is present almost everywhere in the world and loves to feed on sugars. When they do, they release alcohol, water and CO2. We add dried yeast to our wort and let the yeast go to work for about 60 to 72 hours. This results in what is called a “wash”, which is essentially an 8% ABV beer.

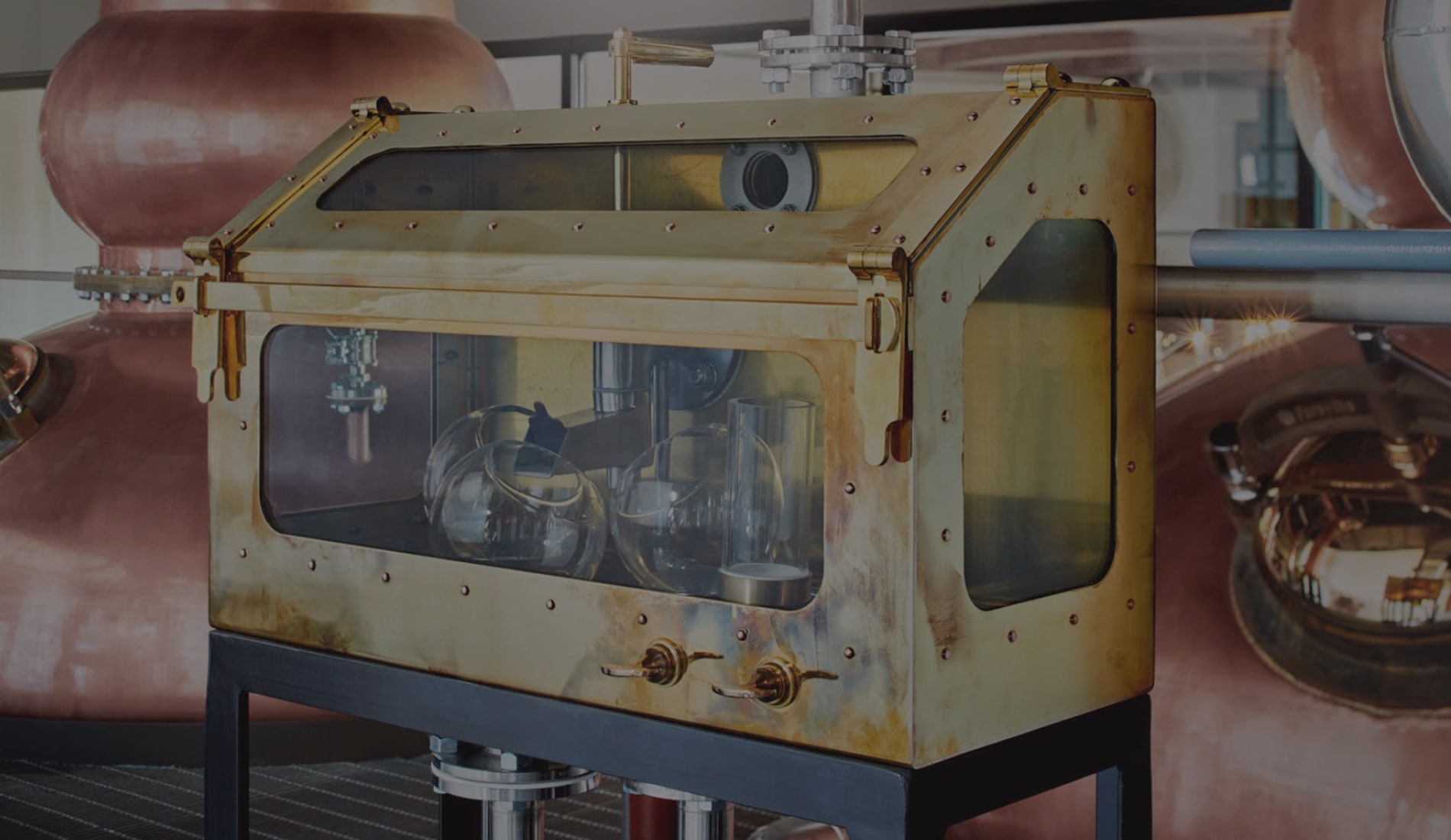

Triple Pot Distilling

This stage is when we transfrom our wash into a whiskey and is the defining characteristic of Irish style whiskeys. Distilling is essentially the process of separating the alcohol from the water to create a desirable high strength alcohol that will deliver an excellent quality whiskey after maturing in oak casks. We call it Triple Pot Distilling because the final liquid has been distilled 3 times, and each distillation takes place in a separate copper pot still.

Wash Distillation: In this first step, we distill the wash to remove all alcohol and flavor and produce an intermediate product known as “low wines”.

Feints Distillation: This is where the science of distillation meets the art. We take the low wines and distill it again, splitting it into two cuts based on the distiller’s taste. The Strong Feints have the most desirable flavor profile and those go to the next still. The Weak Feints get distilled again with the next batch of low wines until they are desirable.

Spirit Still Distillation: This is the third and final distillation where we capture “the heart” of distillate. As liquid comes off the still, it is taken as either heads, hearts or tails. The heads contain too many volatile compounds and their flavor is too strong. The tails don’t contain enough flavor and have an oily impact on the final liquid. So we only use the heart, where we capture the perfect flavor profile we want in our product.

Maturation

In this step, the liquid is moved into barrels. We use American virgin Oak and other types of barrels such as sherry, Malaga, and refill bourbon. It goes into the barrel no higher than 63% abv and we plan to mature it for at least 2 years, but are also planning to have much older expressions. As the seasons change, the liquid in the barrels expand and contract, causing it to move in and out of the wood which adds flavor and color to our liquid. Throughout this process, some of the whiskey evaporates. This is known as the “Angel’s Share”

Blending

The last stage highlights the art of the blender. After the whiskeys have matured over a number of years, each cask may have a slightly different flavor profile. The blender tastes the different whiskey and combines them in the appropriate measures to ensure a perfect flavor profile in every bottle. The blender also takes different whiskey styles and blends them together to create unique flavored whiskeys with the perfect balance of distillate and wood contribution.